INDUSTRIAL PRODUCT COUNTER

An industrial product counter is a specialized device or system used in manufacturing and production environments to count and monitor the number of items produced.

WHAT BENEFITS DOES A SEWING LINE PRODUCTION COUNTER BRING?

The industrial sewing line production counter offers numerous significant benefits for businesses and the production process:

Enhanced Production Efficiency: The counter accurately tracks production output, allowing managers to adjust workflows for increased efficiency.

Quality Control: By monitoring the quantity of products produced, the counter helps in early identification of quality issues, enabling timely corrective measures.

Waste Reduction and Profit Increase: Improved production management leads to reduced material and labor waste, thereby increasing profitability.

Production Data Analysis: Data from the counter provides valuable insights for analyzing performance, helping identify ways to improve production processes.

Effective Labor Management: Information about output helps in optimal allocation of labor resources, ensuring each area or machine is utilized most efficiently.

Rapid Response to Market Changes: The counter enables businesses to quickly adjust production in response to market demands, enhancing competitiveness.

Workflow Optimization: Detailed production data from the counter helps identify bottlenecks and improve workflow processes.

Enhanced Communication and Collaboration: Accurate production data improves communication between departments, from production to management.

Decision Support: The counter provides crucial data for planning production schedules, material ordering, and inventory management.

Employee Motivation: By tracking and acknowledging individual and team contributions, the counter can motivate employees and enhance job satisfaction, while also promoting a team-oriented work culture.

TYPES OF SEWING LINE PRODUCTION COUNTERS

TAL Sewing Line Counter

The TAL Sewing Line Counter is the most popular type of sewing line counter from Vnatech. The counter has a simple, easy-to-use design with a 7-segment LED display. The counter can display information such as:

- Number of products produced

- Production achieved in a day

- Product error rate

- Production speed

- Production target

Far East Foam 2 Sewing Line Counter

The Far East Foam 2 Sewing Line Counter is a high-end type of sewing line counter from Vnatech. The counter has a modern design with an LCD display. The counter can display information similar to the TAL counter, but with higher accuracy and durability.

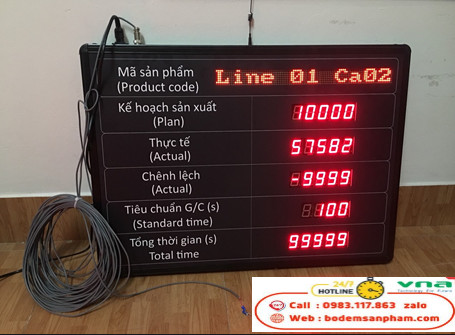

Industrial Sewing Line Production Management Board

An Industrial Sewing Line Production Management Board is a visual tool used in garment factories to track and manage production on sewing lines. It typically consists of a large board or panel that displays key production metrics, such as:

- Target production for the day or shift

- Actual production achieved so far

- Production efficiency

- Quality defects

- Machine downtime

- Operator performance

WHY TO APPLY SEWING LINE PRODUCTION BOARDS IN MANUFACTURING

There are many reasons why sewing line production boards should be applied in production. Here are some of the main benefits:

Improved production visibility: Sewing line production boards provide an overview of the production of a sewing line, including production targets, actual production, defect rates, and machine performance. This makes it easy for managers and workers to track production progress and identify any issues that could impact productivity.

Increased efficiency: By tracking production in real-time, managers can make timely adjustments to the production process to improve efficiency. For example, if actual production is below target, the manager can increase production speed or ask workers to work overtime.

Reduced defects: Sewing line production boards can help identify areas where defect rates are high. This allows managers to take steps to address the issues and improve product quality.

CONSIDERATIONS WHEN USING SEWING LINE PRODUCTION BOARDS IN INDUSTRY

Sewing line production boards are a useful tool that can help manufacturing plants improve efficiency, quality, and productivity. However, to achieve optimal results, it is important to keep the following things in mind when using sewing line production boards in industry:

Choose the right type of board: There are many different types of sewing line production boards available, from simple manual boards to complex electronic boards. The best type of board will depend on the needs and budget of each plant.

Plan the board layout: The location of the sewing line production board is also important. The board should be placed in a location that is easily visible to all workers on the sewing line.

Update information regularly: The information on the sewing line production board needs to be updated regularly to accurately reflect the production situation.